Metal Injection Molding Process

-

Category:Metal Processing & Safety EquipmentMechanical components、Machine tool components

Metal Injection Molding (MIM) Process has 4 advantages:

1. High Complexity: MIM is used to produce products with high complexity.

2. High Accuracy: For production accuracy, MIM is much better than Lost Wax Casting, PM, or Cold Forging.

3. High Quality: MIM is used in producing high density and corrosion resistance products.

4. High Productivity:

MIM is used to produce high volume of products in a short time.

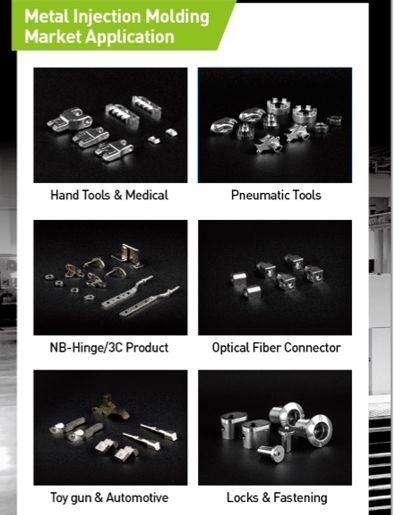

The application of Metal Injection Molding (MIM) Process includes: laptop/3C hinge, fire-arms parts, locks, 3C products, optical fiber connector, automobile parts, hand tool parts, and medical product parts.

1. High Complexity: MIM is used to produce products with high complexity.

2. High Accuracy: For production accuracy, MIM is much better than Lost Wax Casting, PM, or Cold Forging.

3. High Quality: MIM is used in producing high density and corrosion resistance products.

4. High Productivity:

MIM is used to produce high volume of products in a short time.

The application of Metal Injection Molding (MIM) Process includes: laptop/3C hinge, fire-arms parts, locks, 3C products, optical fiber connector, automobile parts, hand tool parts, and medical product parts.

Pao Shen Enterprises. Co., Ltd

- Tel:04-8521181

- Website:https://zh-tw.kw-trio.com/

Owner in CEO Jackson Huang founded Pao Shen Enterprises Co., Ltd in 1976 on the virtues of progress, harmony and innovation.

Pao Shen has manufactured quality stationary and office supplies for over 45 years.

As a world leader in office products and desktop accessories,

we have invested in the most advanced research and tooling facilities to assure the output of high quality products.

Although we are an industry leader, we are always looking for new ways to improve our products and services.

Pao Shen is prepared to face the challenges of an ever-evolving business landscape.

We strive to meet tomorrow’s needs with quality products under the time-honored tradition of “Quality is the best service.”

Our maintained ISO 9001:2015 accreditation is a symbol of our steadfast approach to manufacturing excellence.

A sterling reputation has endowed Pao Shen with prestige that is known the world over.

Under the brand name KW-trio, Pao Shen proudly manufactures products for over 110 countries.

KW-trio provides an excellent selection for lives' needs.

Pao Shen has manufactured quality stationary and office supplies for over 45 years.

As a world leader in office products and desktop accessories,

we have invested in the most advanced research and tooling facilities to assure the output of high quality products.

Although we are an industry leader, we are always looking for new ways to improve our products and services.

Pao Shen is prepared to face the challenges of an ever-evolving business landscape.

We strive to meet tomorrow’s needs with quality products under the time-honored tradition of “Quality is the best service.”

Our maintained ISO 9001:2015 accreditation is a symbol of our steadfast approach to manufacturing excellence.

A sterling reputation has endowed Pao Shen with prestige that is known the world over.

Under the brand name KW-trio, Pao Shen proudly manufactures products for over 110 countries.

KW-trio provides an excellent selection for lives' needs.